Warehouse Command Center

Use Case

For a retailer or a consumer goods company, Warehousing and Transportation together have an average cost of 9% of revenue, while transportation costs are about 5% of sales and need to be optimized (See our Transportation Case studies for a few examples), Warehousing costs come in at about 3% due to labor, equipment, etc. For example, a company with revenue of $50 Billion would be spending about $1.5 Billion in warehousing costs. Even a conservative estimate of bringing in 2% efficiencies in process through technology would mean a productivity gain of a whopping $30 Million per year!

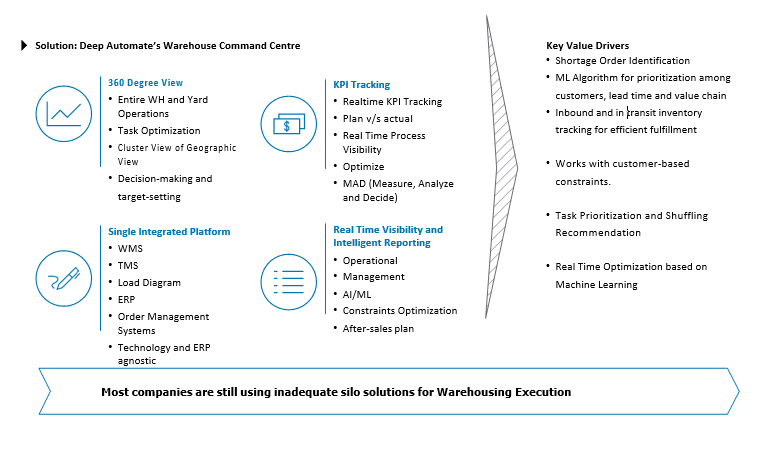

Solution

Warehouse Command Center (WCC) gives you a full operational view of your inbound, outbound, and internal warehouse operational tasks. Measure yourself against key KPI goals (Customizable) and deep dive into any unhealthy KPI and pinpoint issues in real time. Go one step further by integrating key API’s between the Command Center and WMS, TMS, Load Diagram and ERP to submit key decisions on a single user friendly platform. This single platform scales to give you a cluster view of warehouses (Geography) or targeted warehouse view ensuring that you have all the details you need to drive executive and operational decisions.

It’s important to mention that the solution provides the end user with the flexibility to add constraints to the suggested solutions. For instance, the user can specify whether some or all the pallets can be taken from a low-priority customer. If only some pallets need to be reallocated, the user can also set a minimum fill rate that must be met while shuffling the short orders from the low-priority customer.

Furthermore, the solution can optimize the shortage by using one, two, or all three options. For example, the solution may suggest taking some of the quantities from a low-priority customer, deferring the loading of the shorted orders to a later date and time, and using the remaining stock in the yard to reduce the shortage. The end user can choose to implement all three options or only a subset of them based on their specific requirements.

Value Realization:

Warehouse efficiencies:

Operating a warehouse at optimal efficiency is an ongoing journey that needs the operations team to be able to react to various events that occur in real time or can be predicted. Key to this is having insights into warehouse operations as they are happening in real time, ability to get alerted on any delay or problem and having targeted information to act upon. The digital command center brings all this in one platform helping you visualize, act only upon exceptions occurring on the floor and remove bottle necks as they happen.

Manage exceptions:

With our real time Exception Alerting Engine, that not only gives you the root cause of exceptions but also the next actionable steps at the click of a button, helping you save time and effort as you navigate through and ensure operations are seamless.

Manage warehouse capacity efficiently:

Set guard rails on every warehouse operations , which lets you see if any operations is above/below capacity allowing you to tweak the demand/work intake over the week. This helps you smoothen out the tasks over a week on week basis and helps you have a straight line operating mechanism assisting you not only with warehouse operations but also allied functions like transportation where carrier movements can also be smoothened as your warehouse operations get linked.

Improve overall supply chain efficiency:

By linking your warehouse operations to allied functions like Order management system (OMS), Transportation Management system (TMS) ,be assured to have a connected supply chain that gives you an end to end view of your real time operations