Reducing Supply Chain Fines Through Customer Profiling and Allocation Optimization

Motivation

The problem of companies facing fines and charges for failing to deliver orders on time and in full to retailers and supermarket chains is a critical issue that can lead to significant financial losses and damage to the company’s reputation. Therefore, there is an urgent need for a solution that can help companies reduce the on-time in full (OTIF) fines and charges.

Our solution addresses this issue by reducing the shortage, which is the difference between the ordered quantity and the loaded quantity. This can help organizations avoid financial losses and maintain a positive reputation by reducing the shortage.

Our solution focuses on specific scenarios where the client has given the orders with a Required Delivery Date (RDD) window over 48 hours or more. We can leverage the RDD window to mitigate the shortage through various means.

Solution

To help companies reduce shortages for high-priority customers, our proposed solution combines three ways to optimize last-minute product allocation:

The solution utilizes a dynamic customer segmentation algorithm that leverages machine learning to categorize customers into High-priority and Low-priority segments based on various customer properties such as total book of business, total fines charged, frequency of orders, and size of orders. High-priority customers are those who have a solid business relationship with the company and charge higher prices, while Low-priority customers have lesser business with the company and hardly or don’t charge supply chain fines.

To optimize inventory allocation and fulfill orders on time, the solution tracks inbound stocks heading to the distribution centers where the short orders have been identified. The ETA estimation of the inbound stock can be retrieved by integrating tracking devices such as 4kites, CH Robinson etc.

In addition, the solution utilizes unopened stock lying in the yard to reduce the shortage, which helps to minimize waste and improve efficiency. By combining these three options, the solution can effectively reduce the risk of stockouts and improve customer satisfaction.

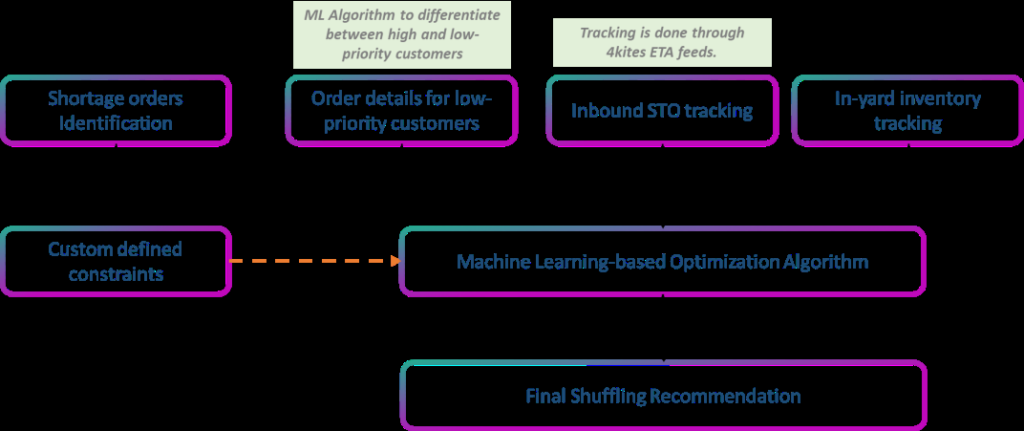

Below is a pictorial representation of how the solution works and is connected to various sources and systems.

Example 1:

- A manufacturing company receives an order from a high-priority customer for 250 pallets of a specific product with a delivery date range of December 22nd to December 25th. On December 21st, the company found that only 150 pallets were available for this customer, resulting in a shortage of 100 pallets. The solution suggests combining all three options to reduce the shortage.

- The solution tracks that 3 low-priority customers have been allocated the same products with 20 pallets each ( Allocation has happened through their Order Management Systems). It also checks from GPS feeds that an inbound stock is estimated to arrive on the 22nd of December afternoon carrying 90 pallets. It also checks and notices that there is no unopened stock in the yard containing the same material that has a shortage.

- The solution will optimize and may recommend taking 10 pallets from each low-priority customer and allocating them to this high-priority customer and deferring the loading time to the 22nd afternoon so that the inbound stocks can be utilized to fulfill the remaining shortage.

Example 2:

- A manufacturing company receives an order from a high-priority customer for 450 pallets of a specific product with a delivery date range of January 1st to January 3rd. On December 31st, the company found that only 200 pallets were available for this customer, resulting in a shortage of 250 pallets.

- The solution tracks that 2 low-priority customers have been allocated same product 50 pallets each and an inbound stock is expected to arrive on 2nd January morning carrying 100 pallets.

- It also mines the internal systems and affirms that there is an unopened inventory in the yard containing 40 pallets of the shorted product.

- It then weighs in all three options and recommends taking 40 pallets from each low priority customers and allocating them to the high priority order. It also recommends using 100 pallets from in-yard inventory and defers to loading to 2nd January to accommodate the remaining shortage from the inbound STO.

It’s important to mention that the solution provides the end user with the flexibility to add constraints to the suggested solutions. For instance, the user can specify whether some or all the pallets can be taken from a low-priority customer. If only some pallets need to be reallocated, the user can also set a minimum fill rate that must be met while shuffling the short orders from the low-priority customer.

Furthermore, the solution can optimize the shortage by using one, two, or all three options. For example, the solution may suggest taking some of the quantities from a low-priority customer, deferring the loading of the shorted orders to a later date and time, and using the remaining stock in the yard to reduce the shortage. The end user can choose to implement all three options or only a subset of them based on their specific requirements.

Value Realization:

Avoiding financial losses:

When companies fail to deliver orders on time and in full, they face fines and charges that can lead to significant financial losses. By reducing the on-time in full (OTIF) fines and charges, companies can avoid these financial losses and improve their bottom line. We noticed one CPG company with about $20 Billion revenue paying fines in excess of $50 Million per year to a top tir.

Improving customer satisfaction:

When companies fail to deliver orders on time and in full, it can lead to dissatisfaction among their customers. This can damage the reputation of the company and lead to a loss of business. By reducing the on-time in full (OTIF) fines and charges, companies can improve their customer satisfaction and retain their customers.

Staying competitive:

In today’s competitive business environment, companies need to be efficient and effective in their operations. By reducing the on-time in full (OTIF) fines and charges, companies can improve their operational efficiency and stay competitive in the market. This can help them attract new customers and retain their existing ones.

Meeting contractual obligations:

Companies that fail to deliver orders on time and in full may not be meeting their contractual obligations with their customers. This can lead to legal disputes and damage to the reputation of the company. By reducing the on-time in full (OTIF) fines and charges, companies can meet their contractual obligations and avoid legal disputes.

Improving supply chain efficiency:

When companies face shortages due to not delivering orders on time and in full, it can lead to inefficiencies in the supply chain. This can cause delays and additional costs for the company. By reducing the on-time in full (OTIF) fines and charges, companies can improve their supply chain efficiency and reduce costs associated with shortages. This can help them become more competitive in the market and improve their overall operations.